It has been a little over two months since I brought a 3D printer (Creality K1 V2) into the house, and I’m finally starting to understand why so many people describe this hobby as a quiet form of engineering meditation. I had my reservations and doubts about 3D printing, because I’ve experienced it some years ago – the state of the art was far from where it is now. But it has gradually turned into a small lab of experiments, prototypes, failed prints, calibrations, and useful items that now live in different places of the house. And this is my best friend now:

Learning the tools: slicers, settings, and first principles

My first weeks were about selecting the right slicer.

Some offered ultra-detailed control at the cost of complexity. PrusaSlicer is a good example of this. A bit complex for my needs: I installed it at first because I had no idea what I was doing, but I quickly realized I don’t need all that complexity. I finally stick with OrcaSlicer (hat tip to my friend Dugi), because it’s a bit more user-friendly and has a lot of presets for different printers.

Anyways, I had kind of trouble to select the right profile for my printer (looks like there are differences of product naming also between Europe and USA).

Materials: a first taste of the filament world

For now, I’ve stayed in the safe zone with PLA and went a bit further with TPU (which by the way caused my nozzle to clog. I panicked, for a while, but I was able to fix it just tearing apart the plastic tube and bearing it with a pair of pliers).

This guy was extremly useful: https://www.youtube.com/watch?v=weeG9yOp3i4

-

PLA has been my reliable material to print, predictable, I’d dare to say almost boring in the best possible way.

-

TPU pushed my printer a bit more. Flexible filament is a different topic: slower speeds, gentler retraction, a little bit of art. Don’t apply too much temperature to the bed, or the print will be too soft. I use it for the keyboard caps in the LCD prototype (see A prototype with LCD GFX and M5Stack keyboard).

-

I still haven’t tested PETG, but it’s next on my list. I want something stronger and more temperature-resistant for outdoor items and functional prints. PLA is nice until you drop it on the floor.

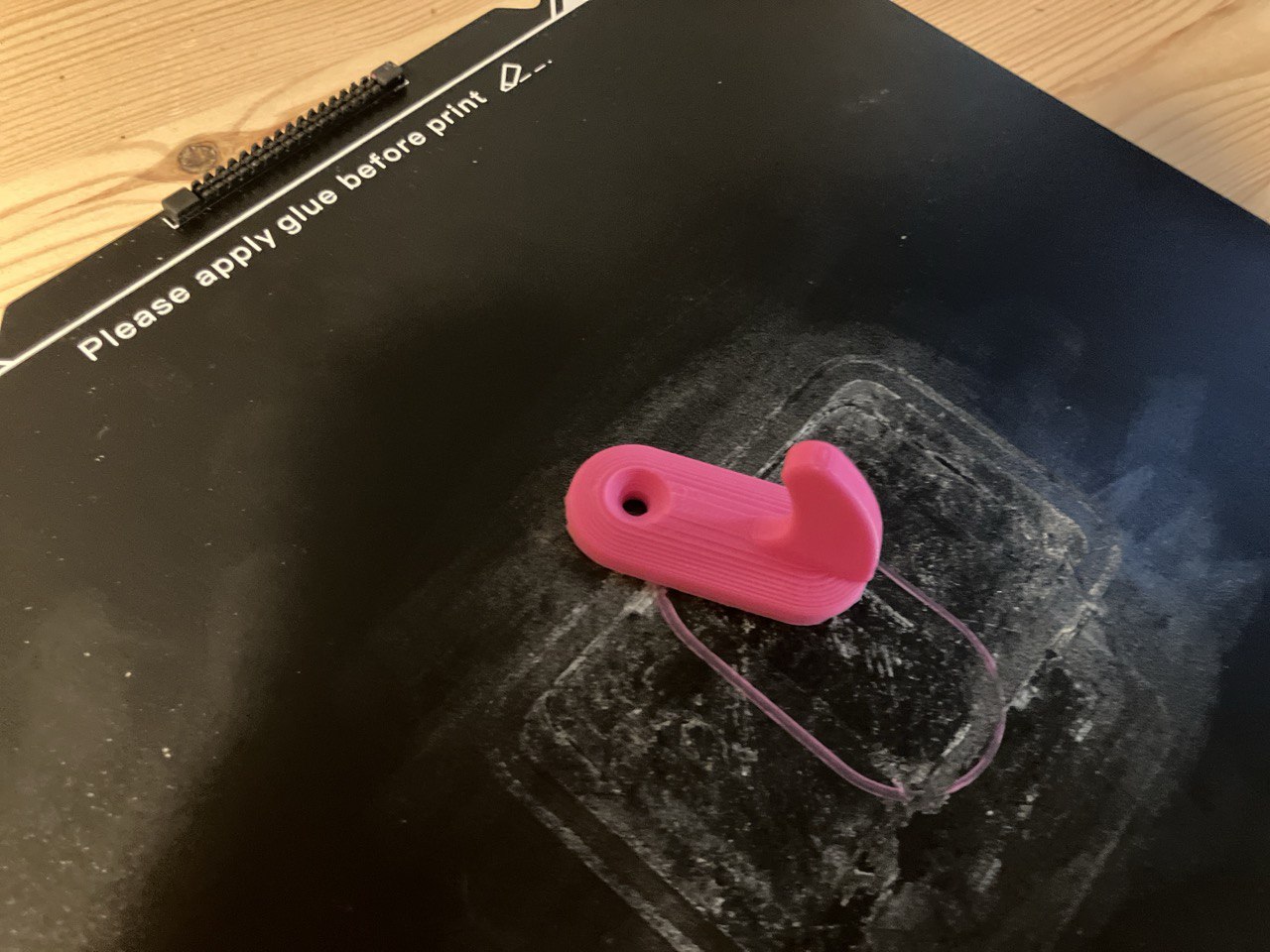

Glue? No thanks!

For the first weeks, I was applying glue to the bed, as recommended by the notice in the bed. But this is not really needed when you can adjust the bed to the recommended temperature for the filament you’re using. And if it is something small, you can add rafts to the print to help it stick to the bed. I’m not sure why this is not the default behavior.

Useful things: Building a workspace that works

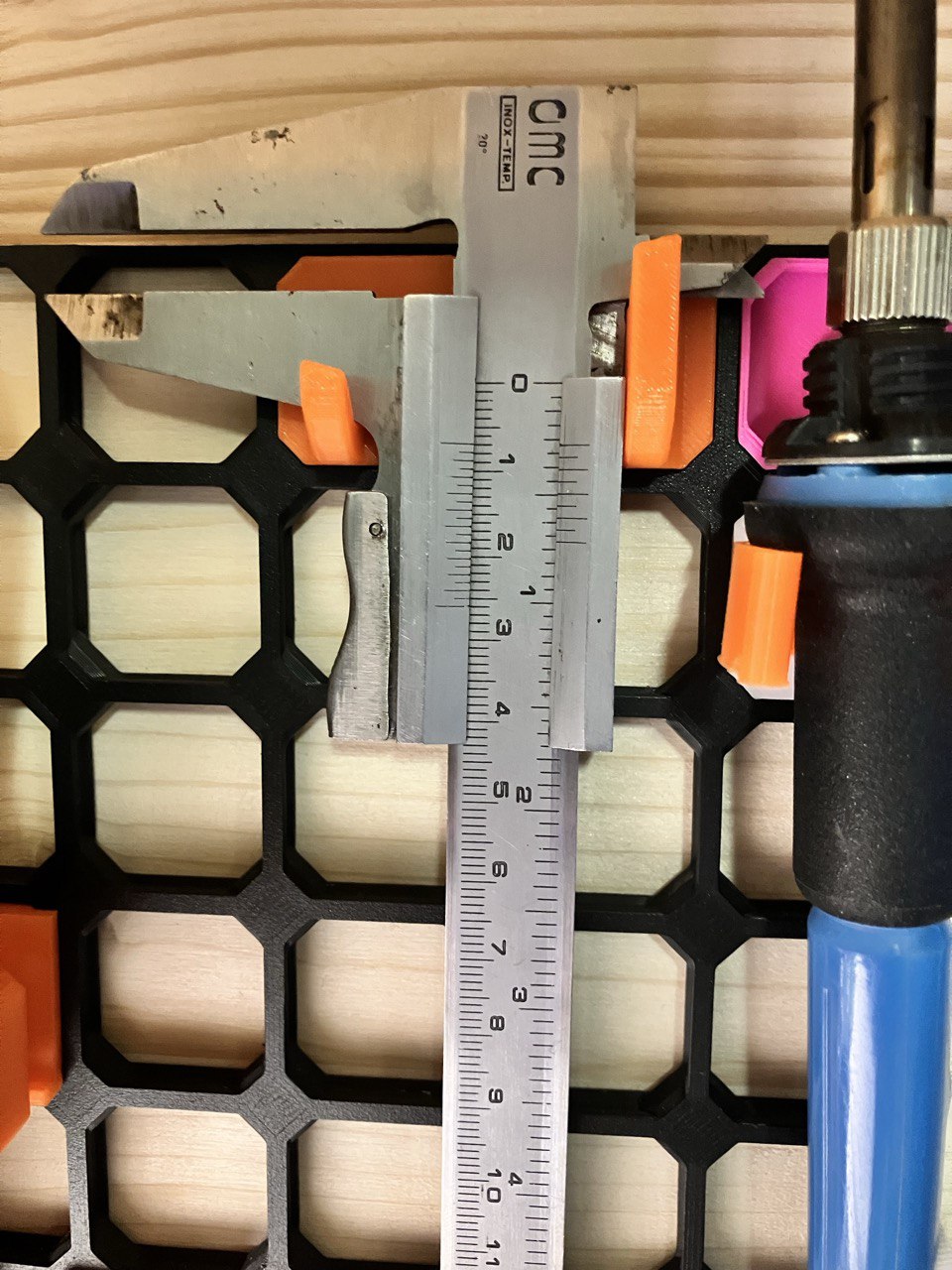

One of my happiest results so far has been a rack for my electronics-repair tools. It started as a necessity-my screwdrivers, tweezers, and spudgers were spreading across the desk like small metallic weeds.

I discovered OpenGrid, which is one of the many 3d modular systems out there (e.g. Gridfinity, Multiconnect, and Underware are other examples). It’s a bit more complex than the other systems, but it’s very flexible and can be used to create a lot of different things.

Designing and printing a custom rack forced me to measure, model, and think in three dimensions. The final result is now permanently installed on my bench, a small reminder that 3D printing can be much more than decorative trinkets.

Fun Prints: bringing ideas Into the house

It wasn’t all functional work. The printer also earned me some parental credibility:

- A few toys for my kids, simple but surprisingly exciting for them.

- A few little hooks for towels and other small items.

- More little toys for family and friends.

- Keyboard fidgets (WASD and arrow keys)

- A Game Boy cartridge organizer.

- A Game holder for for hanging into the OpenGrid system.

- A custom case for my Flipper Zero Dev Board, which finally looks like a proper device instead of wires glued to a PCB.

- And, for sporadic gaming sessions, a dice tower for Hero Quest, which now stands like a tiny fortress in the middle of the table.

Reflections after two months

What I enjoy the most isn’t the prints themselves, but the loop: idea → model → slice → print → adjust → retry.

There’s a calm rhythm to it. The printer hums for hours, the house feels a bit like a workshop from an older era-mechanical, predictable, purposeful. Something is being built, something is being created.

Next step: PETG, more custom designs, and maybe a bigger project that combines electronics and printed parts? Who knows…